For details on the Treetec chainsaw courses please see our Chainsaw Course page.

Below are some commonly asked questions about chainsaw use, training and safety.

Chainsaw use / kickback

We have a lot of enquiries during chainsaw training particularly regarding the dreaded ‘Kickback’. Our course covers the topic in detail however here is the story in case you’re still using the chainsaw between now and the course.

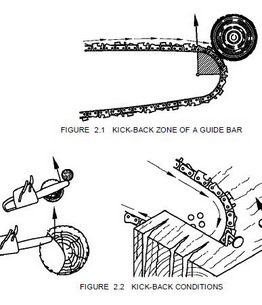

A chainsaw chain travels at about 90km per hour around the guide bar, on each ‘cutter link’ there is the cutting tooth and just in front of it a depth gauge which ensures the tooth only cuts off about .65mm of wood as it passes over the log. Now, as these teeth go around the tip of the cutter bar (the ‘Top quadrant’) the teeth move down and around suddenly exposing the full height of the depth gauge to catch the wood. They are exposed completely and instead of the tooth slicing 0.65mm of timber the depth gauge may grab as much as 5mm of timber, if this happens the chain may stop moving forwards at 90kph and the guide bar will start moving up and backwards at 90kph….towards you. This can also happen if the chain gets pinched causing ‘pull in’ or ‘push out’.

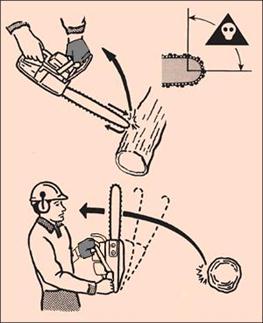

There is no stopping this reactive force with your arms, it’s too quick. The chain may stop rotating around the cutter bar because of the chain break mechanism but that solid metal bar with teeth is still travelling at you with speed. If you operate with your body over the kickback line the bar can strike your neck or head.

So here are the rules:

- Don’t contact the top quadrant of the cutter bar with anything (except once you have safely bored into a log)

- Don’t get the bar pinched, particularly the tip

- Keep your head out of the path of kickback, try and keep your head so you can read the brand name on the left side of the guide bar

- Always wear a helmet with a beak (peak) this slows the bar down as it embeds itself in your forehead, face shields are a great idea too

Chainsaws present lots of risk but if you operate safely and follow some basic rules (including the ones above) they can be used easily and safely by almost anyone.

SAW SAFE USE PROCEDURES

This section discusses the main hazards associated with chainsaw use.

This is a summary of the main hazards and how to reduce risk when using a chainsaw, all operators should have appropriate training and supervision, have read and understood the operators manual, be undertaking regular refreshers and, within the work group be discussing all facets of workplace risk including emergency procedures.

This is a summary of the main hazards and how to reduce risk when using a chainsaw, all operators should have appropriate training and supervision, have read and understood the operators manual, be undertaking regular refreshers and, within the work group be discussing all facets of workplace risk including emergency procedures.

Purchasing and maintenance

All chainsaws should be manufactured and maintained to be compliant with:

Australian Standard AS2726 – Chainsaws Safety Requirements

All chainsaws (and other equipment) must also be maintained in line with the manufacturer’s directions. Maintenance schedules and repairs must be documented.

Training & supervision

- All persons undertaking activities using a chainsaw shall be appropriately trained in their use as per the Competency Standard Unit/s (Refer to the relevant SP AusNet training matrix).

- All staff must be provided with adequate supervision and instruction within the workplace to ensure they are competent and operating safely.

Pre Start Checks

Pre Start Checks

Prior to commencing any work a JSA (Job Safety Analysis) should be undertaken, this is a pre-start check that involves the whole work crew, the JSA should be documented and signed or initialed by all workers on site. It encourages the team to discuss the hazards, builds a better safety culture and demonstrates to authorities that you are complying with OHS / WHS legislation.

Prior to using a chainsaw ensure:

- It is the right size for the job

- It has fuel and oil

- All the safety features are fitted and working (e.g. chain break, chain catcher, spark arrestor, spikes and muffler)

- The air filter is clean and undamaged

- The bar nuts are tight

- The chain is sharp and correctly tensioned

- The operator is fit to work and is wearing the appropriate PPE.

PPE for Chainsaw use

Before commencing work the following PPE should be worn:

Before commencing work the following PPE should be worn:

- Safety helmet preferably with a beak / peak at the front and a face shield

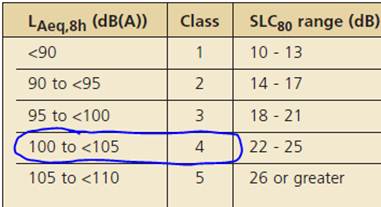

- Hearing protection – Minimum rating of Class 4 (see table opposite)

- Eye protection – Safety glasses to the Aust’ standard, a face shield alone is not adequate

- Steel capped safety boots

- Ankle to wrist clothing (long sleeved shirt & trousers or overalls).

- Workers around power lines should have clothes made from natural fibre of no less than 185gsm (or alternative arc flash protective materials), and fullfil day/night high visibility requirements

- Suitable gloves (gloves must be worn when doing chainsaw maintenance)

- Cut resistant chainsaw chaps / pants

Other equipment

As a minimum there should be the following gear nearby when working:

- Hammer / Axe and wedges

- Sharpening and basic maintenance tools

- First aid kit and access to emergency communications

- 2 stroke fuel and bar oil

- Fire control equipment when there is a higher risk of bushfire

Chainsaw Operation

Fueling

- Fuel up saws in a designated area away from where saws will be started and used

- Allow saws to cool down for at least a few minutes before refuelling

- Handle and store fuel well clear of sparks, open flames or cigarettes

Starting

- DO NOT DROP START*, start saws using the ‘on ground’ method or ‘leg lock’ method

- Ensure the chain break is on

- Use the decompression button if fitted

- Be clear of other people

When using a chainsaw always wear Class 4 or 5 hearing protection.

Note – When operating from a bucket (Elevated Work Platform) or while climbing, drop starting is sometimes appropriate.

General

- Carry the saw with the bar pointing backwards when moving about so that if you trip you don’t land on it.

- Use others to help or a log roller when moving larger sections of wood

- Stabilise wood that could roll, don’t be on the low side of a large log that could roll

- Store saws with a scabbard on and away from delicate equipment particularly ropes and climbing gear

- Have fire fighting gear nearby when operating on higher fire danger days

- Gloves must be worn when doing maintenance

- Don’t do any felling unless you are appropriately trained and certified

Operating

All chainsaw work is to be carried out in accordance with AS-2727 and the operating instructions relevant to the saw.

-

Kickback of a chainsaw is caused by contact between the upper quadrant of the cutter bar and an object. Avoid kickback by NOT using the top quadrant of the cutter bar. (the exception to this is when doing boring cuts)

- Ensure boring cuts are initiated with the bottom quadrant of the guide bar

- Don’t use a chainsaw above shoulder height

- Don’t use a chainsaw one handed, this includes climbers

- If it is a difficult situation; above the shoulders or out on a small limb – use a handsaw

- If a saw is connected to a bucket or person by a lanyard, ensure the lanyard will tear-away under load

- All modern chainsaws are built for right handed use; that is, the left hand is forward and the right hand is on the top or rear handle. This hand position remains the same for left or right handed operators

- Keep your head out of the path of kickback, the operator should be able to read the left side of the guide bar under normal use conditions

- Keep saws sharp and correctly tensioned

- Peak revs should usually be used when cutting

- Don’t operate if other people are too close and ensure nobody is within 3 metres in front of you when cutting in case a chain breaks

- Stabilise wood when cutting so that the chain doesn’t grab and pull pieces into your shin and also to ensure log sections don’t roll away

- Identify compression and tension wood for each cut – cut compression first

- Wrap your thumbs

- Use your front hand to operate the chain break (don’t bring your rear hand over for either engaging or disengaging the chain break)

- Engage the chain break when not cutting

- Right foot forward when doing horizontal cuts, left foot forward for vertical

Running on

When using a chainsaw the chain should stop moving around the bar when the saw is idling, the chain should only start spinning once revs are increased.

Running-on is usually caused by a spring within the centrifugal clutch breaking, although it can also be the idle is set too high. When the spring breaks it allows the clutch plates to engage the clutch drum even with low revs and so casuses ‘running on’ and makes the saw very dangerous.

Running on is an issue that needs to be fixed promptly because if you manage the problem by engaging the chainbreak it’s like driving a car with the handbrake on and you will damage or destroy the clutch.

REFERENCES

AS 2726 Chainsaws – Safety Requirements

AS 2727 Chainsaws – Guide to Safe Working Practices

For more information or a quote please email, phone 03 8644 8005 or complete the form below: